Dust Collectors

A dust collector is an essential piece of air filtration equipment designed to enhance air quality in commercial and industrial environments. By capturing airborne particulate matter—such as dust and other pollutants—it ensures that cleaner air is released into the atmosphere. These systems are instrumental in filtering out solid particles and hazardous pollutants that regulatory agencies have restricted due to their contribution to air pollution.

The History of Dust Collectors

The need for dust collection systems emerged in the 19th century during the Industrial Revolution, as factories began generating large volumes of fine dust, wood dust, and other airborne contaminants. In 1852, S.T. Jones, an American inventor, filed a patent for one of the earliest dust collector designs, known as the single bag filter. This innovation laid the groundwork for future developments in industrial air filtration.

In 1921, Wilhelm Beth, an engineer from Lübeck, Germany, significantly advanced dust collection technology by patenting three key filtration methods. His contributions included cloth filtering systems, mechanical shaking devices for filter cleaning, and tubular filter designs, all of which played a crucial role in improving air and gas filtration. His work also led to the development of hose filters, which became widely used in industrial settings.

The 1950s marked a turning point in air filtration technology with the invention of the reverse air jet system, which dramatically improved dust collection efficiency. By the end of the decade, engineers introduced the pulse jet filtration system, a breakthrough that reduced the number of moving mechanical components in dust collection equipment, making the process more reliable and cost-effective.

As environmental regulations tightened in the 1970s and 1980s, industries increasingly turned to dust collectors to comply with stricter air quality standards. Since then, manufacturers have continued to refine dust collection systems, developing smaller, more effective, and highly efficient filtration solutions.

Benefits of Dust Collectors

- Dust collectors provide numerous benefits, making them indispensable in industrial settings. They significantly reduce the risk of fire by capturing combustible dust before it accumulates. They help prevent dust explosions, a serious hazard in facilities handling fine particulate materials. By maintaining air clarity, they improve visibility on job sites, creating a safer working environment. Additionally, they mitigate industrial odors, improving overall workplace conditions. Beyond these advantages, dust collectors offer low operating costs and high efficiency, making them a practical investment for long-term air quality management.

Why Use a Dust Collector

Dust collection systems are designed to capture airborne particles generated during industrial processes. These particles pose serious risks to worker health and can damage sensitive equipment if left unfiltered. Without proper dust collection, contaminants accumulate in facility air, leading to respiratory issues, machinery malfunctions, and safety hazards. A well-engineered dust collection system addresses these concerns by drawing contaminated air through filtration mechanisms that trap hazardous particles, ensuring that only clean air is recirculated back into the workplace or released into the atmosphere.

Beyond improving workplace conditions, dust collectors are crucial for regulatory compliance. Occupational Safety and Health Administration (OSHA) standards mandate strict indoor air quality requirements to protect workers from airborne contaminants. Similarly, the Environmental Protection Agency (EPA) and other regulatory bodies impose limits on industrial emissions, requiring companies to implement effective dust control measures.

Dust collection is vital in numerous industries where airborne particulates pose environmental and operational challenges. Facilities involved in coal handling, cement fabrication, metal fabrication, mining, chemical processing, woodworking, pharmaceuticals, recycling, and agriculture all depend on dust collection systems to maintain clean, compliant, and efficient operations. Companies may integrate multiple dust collector types into a comprehensive system or utilize self-contained, portable units to address specific dust control needs. As industries continue to prioritize air quality and environmental responsibility, dust collection systems remain essential for sustainable and safe manufacturing practices.

Dust Collector Design

Industrial dust collectors vary widely in type, size, and configuration, with each model designed to meet specific air filtration needs. Regardless of their differences, all dust collectors consist of multiple components, and their manufacturing process involves a combination of machining and assembly.

A fundamental part of nearly every dust collector is the blower, which requires precise engineering and fabrication. To create this critical component, manufacturers must design and produce an engine, fan blades, a wheel or rotor mounted on a shaft, and a durable housing. Beyond the blower, dust collectors incorporating fabric or compact filters, such as cartridge filters, demand the production of additional components, including a blow pipe, housing, hopper, clean plenum, dusty plenum, tube plate, compressed air header, filter bags, cages, and more. Each part must be carefully designed and manufactured to ensure seamless operation and long-lasting performance.

After manufacturing and assembling the dust collector’s components, secondary processes can enhance durability and efficiency. For instance, fabric filters are often treated with a pre-coat or filter enhancer to extend their lifespan and improve filtration efficiency. The most commonly used pre-coat material is chemically inert limestone, which prevents clogging and enhances particle capture.

The external frame or housing of a dust collector is typically built using robust metals such as mild steel or stainless steel, ensuring structural integrity and resistance to industrial wear. Fabric filters, a key component of many dust collection systems, can be made from various materials, including felted cotton, woven cotton, synthetic fabrics, or glass fiber material, each offering unique benefits depending on the application.

For further customization, manufacturers can tailor dust collectors with specialized panels, industrial-grade paint coatings, and additional accessories such as tailpipe adaptors. Retrofitting options are also available, allowing operators to upgrade their systems to meet evolving industry requirements and improve overall efficiency.

Dust Collector Images, Diagrams and Visual Concepts

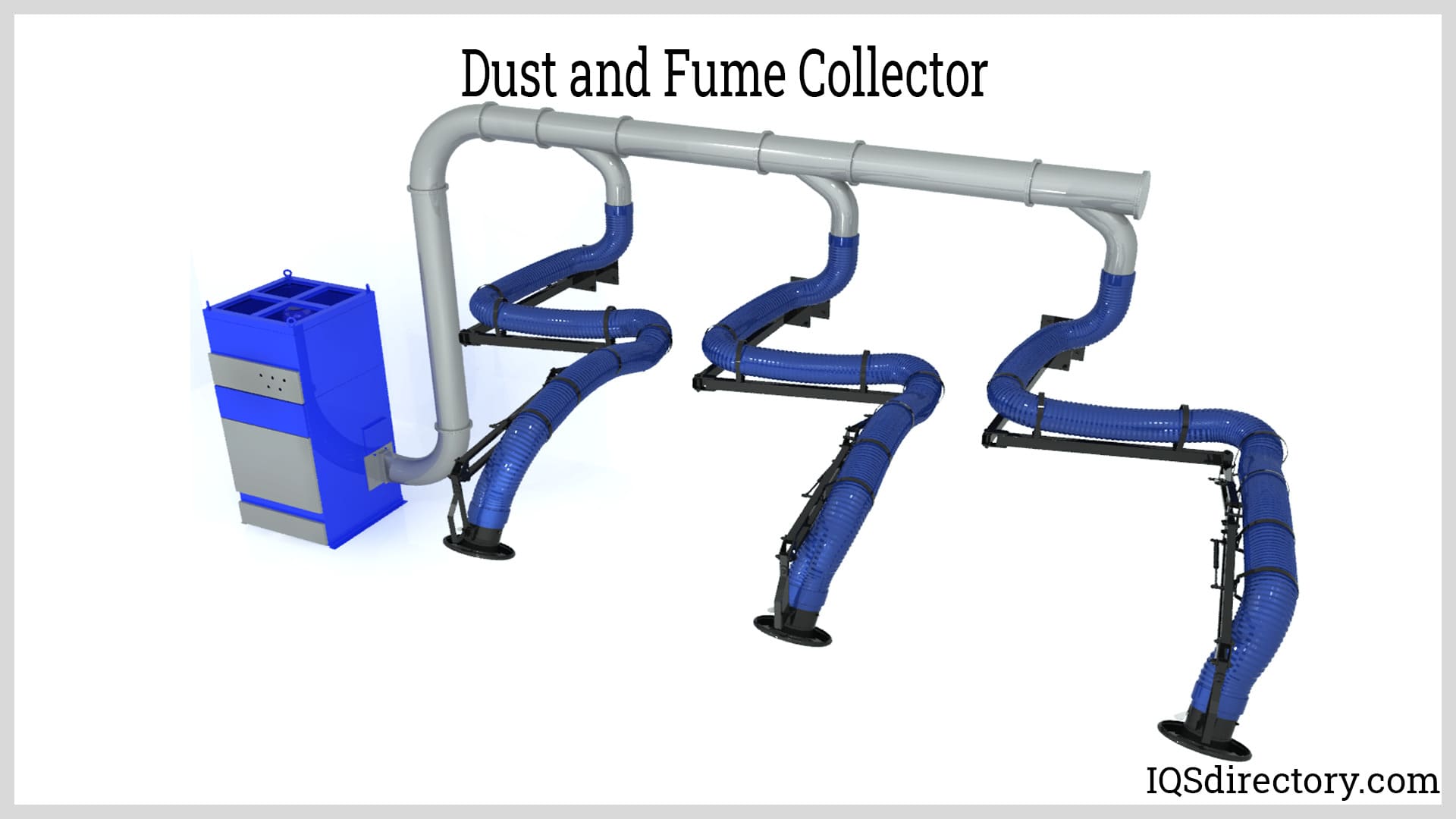

A dust collection system, a system that removes particulate contaminants from the air in production facilities, workshops, and industrial complexes.

A dust collection system, a system that removes particulate contaminants from the air in production facilities, workshops, and industrial complexes.

When the air is cleaned, the particulate contaminants are expelled outside or recirculated, after the achievement of the proper emission‘s standards.

When the air is cleaned, the particulate contaminants are expelled outside or recirculated, after the achievement of the proper emission‘s standards.

The baghouse is the most common and the most efficent form of dust collection systems.

The baghouse is the most common and the most efficent form of dust collection systems.

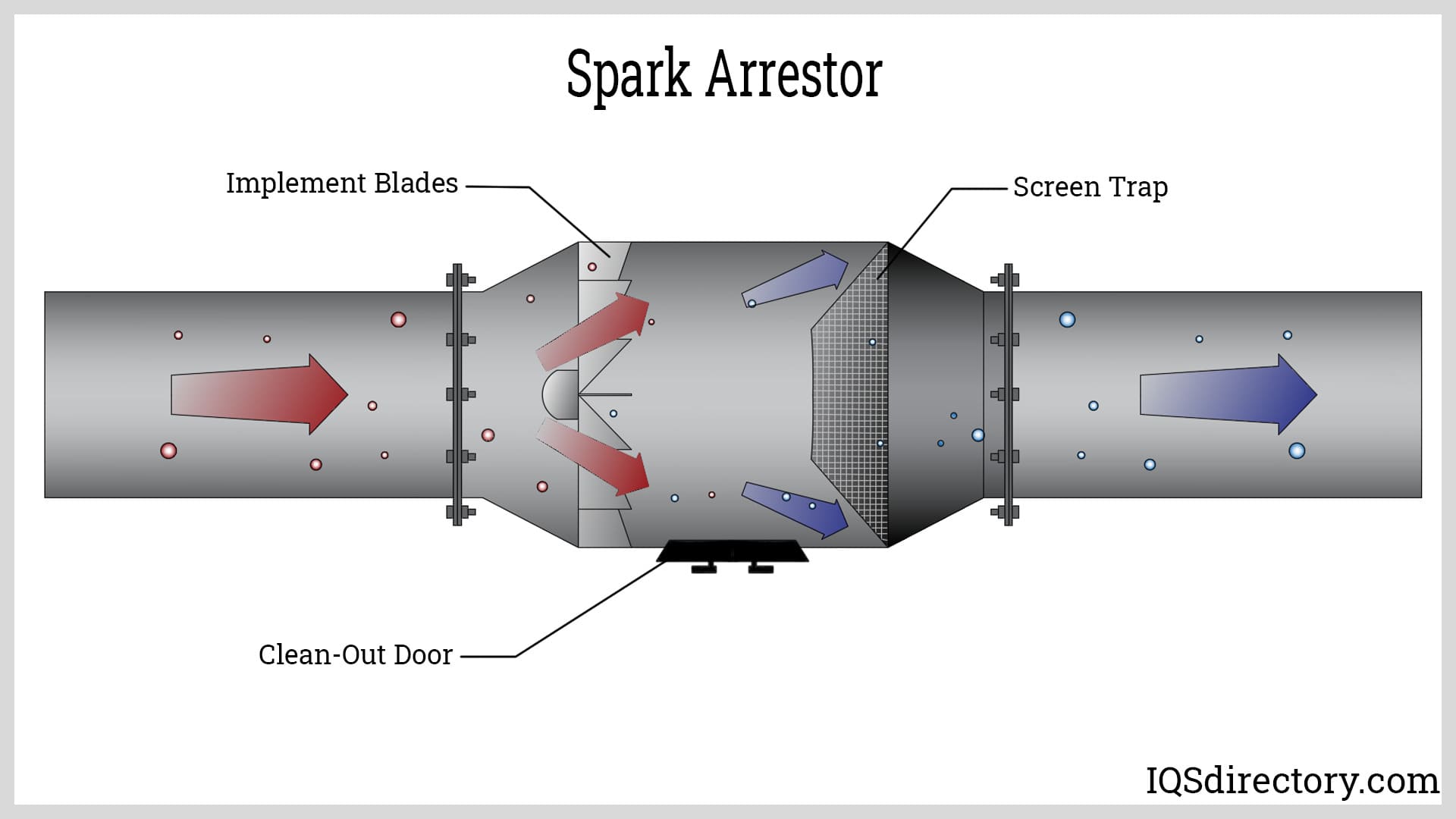

A spark arrestor is used for combustion preventative and is an add-on for systems that have potential for combustion, which traps exhaust and lower the temperature before the particles enter the dust collecting device.

A spark arrestor is used for combustion preventative and is an add-on for systems that have potential for combustion, which traps exhaust and lower the temperature before the particles enter the dust collecting device.

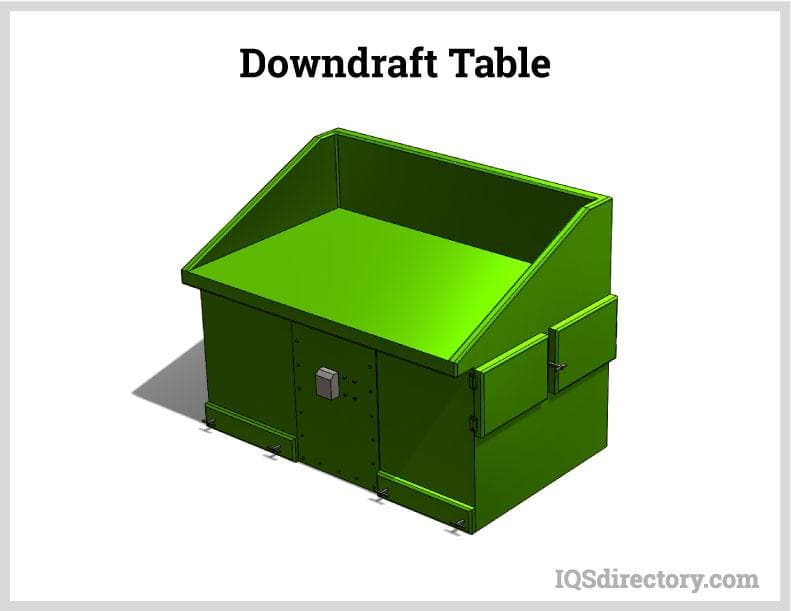

Downdraft tables are self-contained dust collection systems that remove particulate matter from the surface into a filtration system.

Downdraft tables are self-contained dust collection systems that remove particulate matter from the surface into a filtration system.

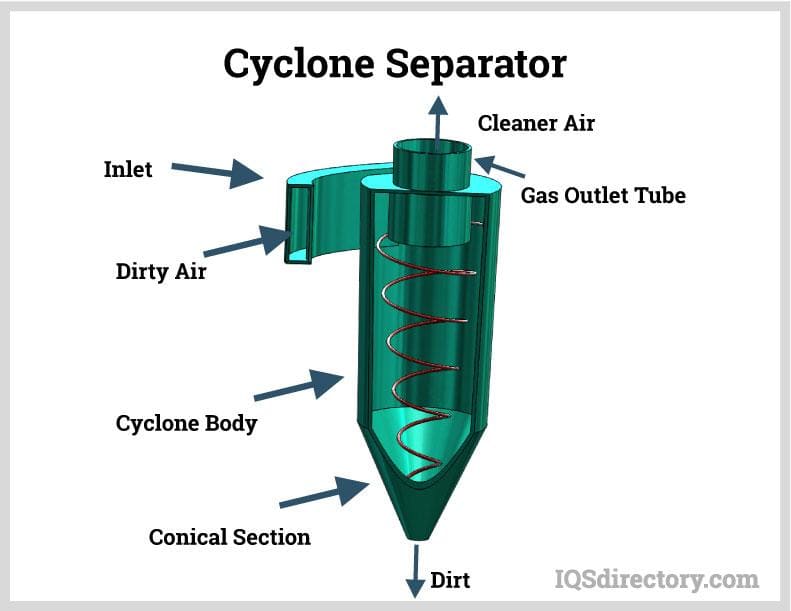

Cyclone dust collection systems are a form of inertial separator that uses centrifugal force to separate particulates, which that the cyclone in the self-contained chamber where the air is purified.

Cyclone dust collection systems are a form of inertial separator that uses centrifugal force to separate particulates, which that the cyclone in the self-contained chamber where the air is purified.

The most common material removed by a dust collection systems.

The most common material removed by a dust collection systems.

Dust Collector Types

- Baffle Chambers

- Disrupt airflow to force heavier dust particles downward using gravity and inertia, removing them from the air stream.

- Baghouse Type

- Use filters made from glass fibers or fabric to efficiently capture fine particulates.

- Cartridge Collectors

- Feature a high surface area, improving airflow, reducing resistance, and minimizing cleaning frequency.

- Cyclone Dust Collectors

- Rely on centrifugal force to separate dust from the air.

- Cyclone Separators

- Spin air inside a tank, forcing heavier particles against the outer wall, where they drop into a collection chamber. Multi-cyclone models contain multiple cyclone cylinders, while single-cyclone models have just one.

- Downdraft Booths

-

Vent from the top, pulling dust and fumes upward and away from workers.

- Downdraft Tables

- Feature perforated tabletops and back walls that draw contaminants away from the breathing zone.

- Dust Collecting Systems

- Filter airborne particulates before releasing purified air back into the environment.

- Electrostatic Precipitators

- Ionize dust particles, causing them to adhere to positively charged collection plates for effective removal.

- Fabric Collectors

- Use fabric filters made of woven cotton, felt, or glass fiber to capture over 99% of fine dust particles. These systems pull air through fabric bags, trapping dust while allowing clean air to exit. Residual dust clings to the filter or settles into an airlock at the bottom of the hopper.

- Industrial Dust Collectors

- Maintain clean air standards in manufacturing environments by minimizing pollutants.

- Inertial Separators

-

Redirect gas streams, forcing dust particles to separate from the airflow.

- Jet Dust Collectors

- Utilize jet-based cleaning cycles for efficient dust removal.

- Portable Dust Collectors

- Mobile systems that can be repositioned as needed.

- Pulse Jets

- Use compressed air bursts to expand fabric bags violently, dislodging trapped dust.

- Settling Chambers

-

Slow down dust-laden air, allowing heavier particles to settle naturally.

- Silo Vents

- Collect airborne particulates in filter bags during the silo-filling process, with shaken bags returning valuable material to storage.

- Small Dust Collectors

- Provide air filtration solutions for confined spaces.

- Unit Collectors

- Compact systems containing a fan and either a fabric or cyclone collector, offering cost-effective solutions for smaller operations.

- Shop Vacuum

- Use centrifugal fans to pull in dust-laden air, trapping particles in fabric bags or cyclone chambers.

- Ventilators as Dust Collectors

- Continuously draw in and filter airborne particles.

- Wet Dust Collectors

- Utilize water to saturate dust-laden air, separating particulates through pressure drops.

- Wet Scrubbers

- Introduce liquid streams to capture dust from gas emissions, effectively purifying the air. Different scrubber designs optimize efficiency based on energy usage and industrial applications.

-

-

Installation of a Dust Collector

Installing a new or retrofitted dust collector requires careful planning and coordination with your supplier, who will assist based on the size and complexity of your system. Large-scale dust collection systems often require professional installation support, including safety measures and specialized equipment such as cranes and lifts. In contrast, smaller systems, like shop vacs, may only need delivery and minimal setup. If you plan to handle the majority of the installation yourself, consult with the manufacturer beforehand to ensure you fully understand the process and have the necessary tools to complete the job correctly and safely.

Standards and Specifications of Collectors

Compliance with safety and regulatory standards is essential when installing and operating a dust collector. To ensure legality and protect employees, follow OSHA (Occupational Safety and Health Administration) guidelines. Since dust collectors help businesses meet government restrictions on emissions, manufacturers should also design systems in accordance with EPA (Environmental Protection Agency) regulations. Adhering to these standards ensures a safe and compliant work environment while optimizing system performance.

Things to Consider When Purchasing a Dust Collector

- Choosing the right dust collection system requires evaluating several key factors:

- Indoor vs. Outdoor Application: Determine whether the system will be installed indoors or outdoors to ensure proper ventilation and compliance with space constraints.

- Dust Density: Assess the density of the dust particles to select the most effective filtration and collection method.

- Operational Size: Consider the scale of your operation to match the system capacity with your dust collection needs.

- Usage Frequency: Evaluate how often the system will be in operation to choose a unit that can handle continuous or intermittent use efficiently.

- Substance Type: Identify the specific substances your system will be collecting, whether it’s dust and fumes, liquid and fumes, or other particulates, to ensure compatibility with the appropriate filtration technology.

- Once you've determined the specifications for your dust collection system, selecting the right manufacturer is just as important as choosing the right equipment. The ideal manufacturer is not only experienced and skilled but also responsive, reliable, and committed to excellent customer service. To find the best fit, explore reputable manufacturers listed at the top of this page and assess their expertise, product offerings, and service quality.

Proper Care for Dust Collectors

Maintaining a dust collector requires regular filter cleaning to ensure optimal performance. When the filter cake on baghouse filters becomes too thick, it increases system stress and restricts airflow. While some baghouses come equipped with vibrators that shake dust loose, manual cleaning is still necessary from time to time to maintain proper efficiency.

Beyond filter maintenance, cleaning other components such as dust collection hoses and ducting is equally essential. Neglecting ducting can lead to increased friction and excess static pressure, reducing overall system effectiveness. Regular inspections and upkeep of these components prevent performance issues and prolong the life of the dust collector.

Dust Collector Accessories

A variety of accessories can enhance the performance and functionality of a dust collector, depending on the specific system in use.

Available accessories include:

Slide Gates: Control airflow by opening or closing access points.

HEPA Air Filters: Provide high-efficiency filtration to capture fine particulates.

Dust Drawers: Offer easy collection and disposal of accumulated dust.

Explosion Doors: Improve safety by venting pressure in case of an explosion.

Ducting: Ensures proper airflow and transport of collected dust.

Extra Duct Ports: Allow for additional connection points to improve system versatility.

Multiple Suction Hoods: Capture dust at multiple points in the workspace.

Flexible Exhaust Hoses: Provide adaptability for different installation layouts.

Sprinkler Systems: Enhance fire safety by suppressing airborne dust ignition.

Emission Sensors: Monitor air quality and detect pollutant levels.

Rotary Valves: Control the discharge of collected dust.

Tailpipe Adaptors: Facilitate connection to external ventilation or exhaust systems.

Gas Detectors: Detect hazardous gas levels for improved workplace safety.

To determine which accessories best suit your application, consult your supplier for expert recommendations tailored to your dust collection system.

Dust Collector Terms

- Air-to-Cloth Ratio

-

The amount of process gas or air entering the fabric collector (baghouse) divided by the square feet of cloth in the fabric collector.

- Asbestosis

-

A form of pneumoconiosis caused by inhaling asbestos minerals, leading to lung scarring, breathing problems, and various forms of cancer.

- Bleedthrough

-

The ability of dust or fume particles to migrate through the fabric bag.

- Cake

- Dust buildup on the filter medium surface during filtration, often aiding in the filtration process.

- Certified Energy Manager (CEM)

- An international professional designation available through training and testing by the Association of Energy Engineers (AEE).

- CFC (Chlorofluorocarbon)

- A family of refrigerant chemicals, including R-11, R-12, R-113, R-114, and R-115, phased out due to their impact on stratospheric ozone depletion.

- Coating

- The process of dipping a filter medium into a solution to lubricate fibers and reduce self-abrasion.

- Collection Plates or Tubes

- Electrodes in an electrostatic precipitator that attract and collect negatively charged dust particles.

- Concentration

- The amount of dust present in gas or air, measured in grains per cubic foot or pounds per hour.

- Discharge Electrodes

- Electrodes in an electrostatic precipitator that negatively charge dust particles.

- Electrodes

- Conductors or semiconductor parts that create electrical connections with nonmetals or control electron movement.

- Fabric Bag

- A filter in a fabric collector made from woven or felt materials such as cotton.

- Fibrogenic Dust

- Toxic particles that penetrate the lungs, causing lung dysfunction and scar tissue formation.

- Filter Media

-

A porous barrier used in filtration to separate particles from fluid streams.

- Flange-to-Flange

-

The section of a fabric collector from the inlet flange to the outlet flange.

- Flex Abrasion

-

Wear on cloth in a fabric bag caused by excessive bending.

- Hood

- A hood-shaped inlet designed to collect contaminated air and direct it into the exhaust system of a baghouse.

- Hopper

-

The area in dust collection systems where collected dust is stored.

- Inert Dust

- Dust particles composed of less than one percent quartz and other silicates.

- Inhalable Dust

- Medium- to large-sized dust particles that do not reach the lower respiratory tract but remain in the upper respiratory system, including the nose and throat.

- Mist Collector

- A device that removes fine fluid particles, such as oil mist and dry smoke, using a three-phase motor to force mist particles into a drum, where they coalesce and return to the machine’s coolant tank while clean air is exhausted.

- Multi-Cyclone Separators

- Centrifugal separators containing multiple parallel cyclones that separate dust particles based on texture.

- Plate Precipitator

- A common high-voltage electrostatic precipitator consisting of flat collection plates with discharge electrodes.

- Pneumoconiosis

-

A respiratory ailment caused by excessive inhalation of metallic or mineral dust, including diseases such as silicosis and asbestosis.

- Rapper

-

A component of an electrostatic precipitator that transfers dust from collection plates to the hopper.

- Respirable Dust

- Small dust particles that reach the lower lungs, contributing to pneumoconiosis.

- Silicosis

- An incurable, potentially fatal form of pneumoconiosis caused by inhaling silica dust, leading to lung diseases such as emphysema. The disease progresses even after exposure ends.

- Surface Abrasion

- Consistent wear on the dirty side of fabric bag cloth.

- Spark Arrestors

- Devices that intercept flammable debris from combustion sources to prevent fires. Early versions, often spiral-shaped cones, were used in steam locomotives to separate embers from exhaust via centrifugal force.

- Total Dust

-

Includes all dust particles, whether respirable or inhalable.

- Tubular Precipitator

- A high-voltage electrostatic precipitator featuring cylindrical collection plates that rotate around discharge electrodes.

- Vibrator Systems

- Components of an electrostatic precipitator that transfer dust from collection plates to the hopper.